Giotto

The state of the Art

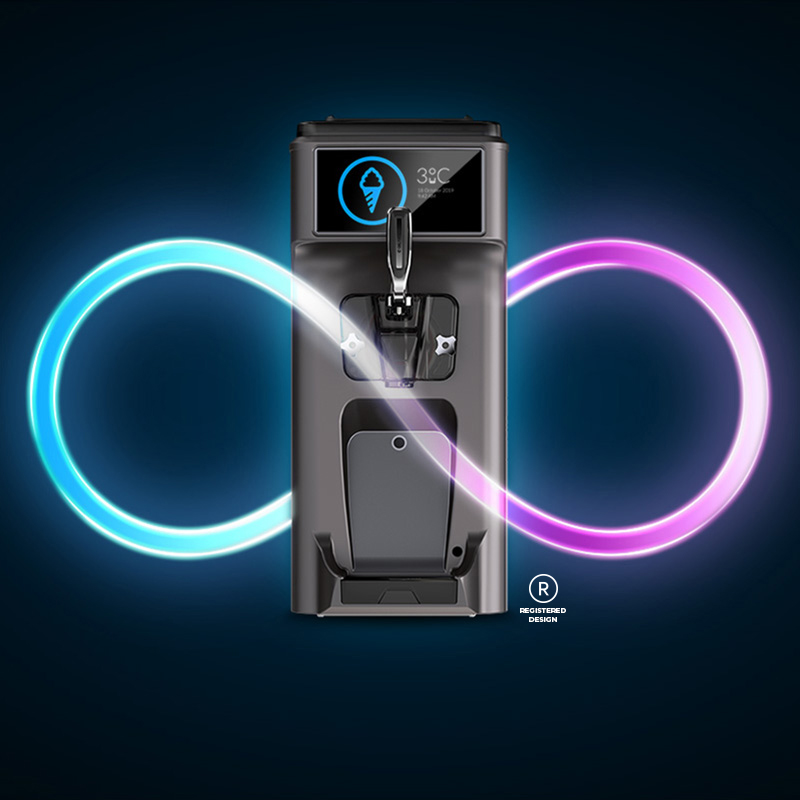

Giotto

Giotto marks a new era for the world of ice cream machines. With its unique personality and great functionality, Giotto is the result of painstaking design work that boosts Gel Matic 4.0 technology. No detail has been overlooked, ensuring that the machine is easy to use and guarantees excellent performance and accurate control, while minimizing machine downtime and extending the life of each component. Giotto is not just a machine, it is a system, one that accompanies the user at every stage in the production process and that guarantees predictive analytics and assistance.

Unique identity

Giotto stands out for its overall look and fine details. Each and every line has been carefully designed to give Giotto its distinct identity. Alongside the care taken over its aesthetics, a lot of attention has also been given to making Giotto highly practical and functional, for both form and performance excellence.

Smart placement

Just 30 cm deep, Giotto is the perfect combination of form and function. All standard activities are controlled from the front panel, for maximum ergonomics and ease of use. Upwards air flow means the machine can be installed in tight areas. The absence of cables makes it easier to manage and service, as well as ensuring that Giotto can fit into any setting, turning the offer of ice cream into a real business opportunity.

Predictivity

The latest version of the In.Co.Di.S. control system has been developed in accordance with ‘Industry 4.0’ technology, for greater man-machine interaction, with predictive capacity, making it possible to anticipate problems, identify the correct solutions and improve performance, thereby cutting machine downtime. The user is guided through each stage of the process and remote control offers the chance to analyze machine performance and intervene as necessary from anywhere in the world, and in real time. Heat treatment (HT) comes as standard, reducing the need for frequent wash cycles and guaranteeing respect of hygiene protocols.

Inverter

The inverter improves many functional aspects of the machine, especially its reliability, efficiency and ice cream quality. Greater control over the range of processes lessens the risk of anomalies and guarantees longer life for components. Partialization of the power input reduces consumption levels appreciably. Beater speed control means the machine can be used to produce various different products, such as ice cream, milkshakes, soft ice, frozen yogurt and frozen beverages.

Eco-friendly

Giotto is not just beautiful to see: it also has a beautiful soul, as it is eco-friendly. Designed to run with the minimum of gas, it also prefers the least polluting ones. Last but not least, Gel Matic has been designed to offer acoustic comfort, as its structure reduces the propagation of sound pressure.

In.Co.Di.S.

A new generation interactive control and diagnosis system conceived to help the user at every stage of production, it also constantly monitors machine performance. The wide, elegant 7″ touch screen display allows for intuitive use of the different functions thanks to a series of icons specifically designed to be immediately understood. A thorough study of touch gestures – finger movements on the screen – makes the interface user friendly and completely natural.